VPC Plant Capabilities: Up to 7.6 meters Profile Length

HPC Plant Capabilities: Up to 8.2 meters Profile Length

Yearly capacity 9100mT

Powder Coating

Gulf Extrusions LLC offers a variety of grades of Thermosetting Powder coatings, including Epoxy, FBE, Epoxy- Polyester, Architectural Polyester, hybrids, Polyester, Super Durable Polyester, Polyurethane.

Powder Coating Benefits

- Increased durability: Powder coated aluminium can last for many years with minimal maintenance.

- Lasting protection: Powder coating offers high resistance toward heat, acids, humidity, salt, detergents, and UV.

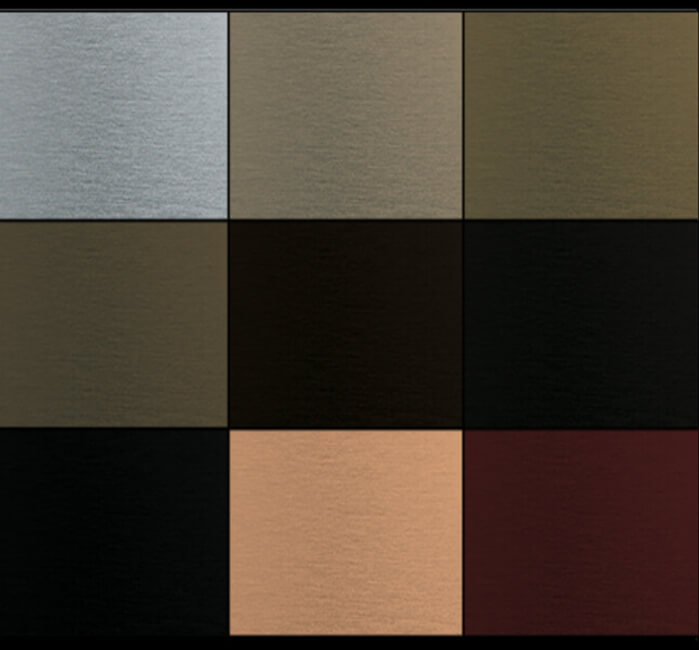

- Specialized finishes: Varieties of surface finishes (rough, smooth, texture) and a wider color and gloss range.

- Environmentally friendly: Powder coatings emit zero volatile organic compounds (VOC), and production lines produce less hazardous waste than conventional liquid coatings.

- Lower overall material costs: powder coating is cheaper as compared to traditional painting methods.

- Aesthetic appeal: Powder coated items generally have fewer appearance differences with more consistent and durable surfaces.

Powder coating with Gulf Extrusions

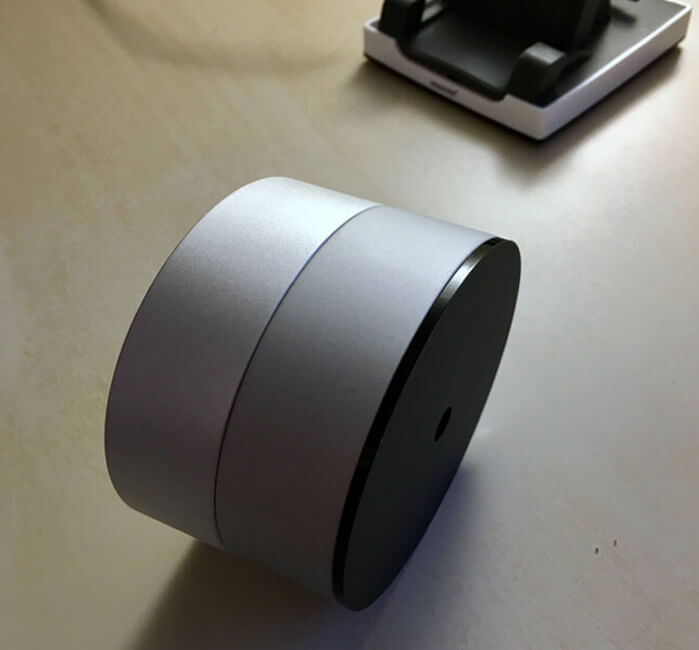

We offer powder coating service for aluminum extrusions, machined aluminum components, and fabricated aluminium parts, for up to 8.2 meters in lenght. Powder coating is extensively utilized in a wide range of industries including kitchen appliances, bicycles, automotive and transportation parts, office furniture, air conditioners, marine equipment, pipes, and building components like window frames, curtain walling, cladding, pressings, louvers, and handrails.

Our powder coating plant is equipped with precision instruments especially designed to control the quality of profiles and to ensure that the specifications set by local and international standards are met.

Range of Durability and Applications: Gulf Extrusions LLC Being an approved applicator for a range of powder coating finishes:

- PEF CLASS 1 (Standard Powder): Provides a basic level of durability suitable for many applications.

- SDF CLASS 2 (Super Durable Powder): Offers enhanced durability, making it ideal for products exposed to harsh environments or frequent use.

- HDF CLASS 3 (Hyper durable, Durasul Powder): Represents the highest level of durability, providing exceptional protection against extreme conditions and extended lifespan.

Compliance with Standards: It’s crucial for powder coatings to meet international standards to ensure quality and performance consistency. Gulf Extrusions LLC complying with QULAICOAT and AAMA indicates a commitment to meeting industry benchmarks for product excellence.

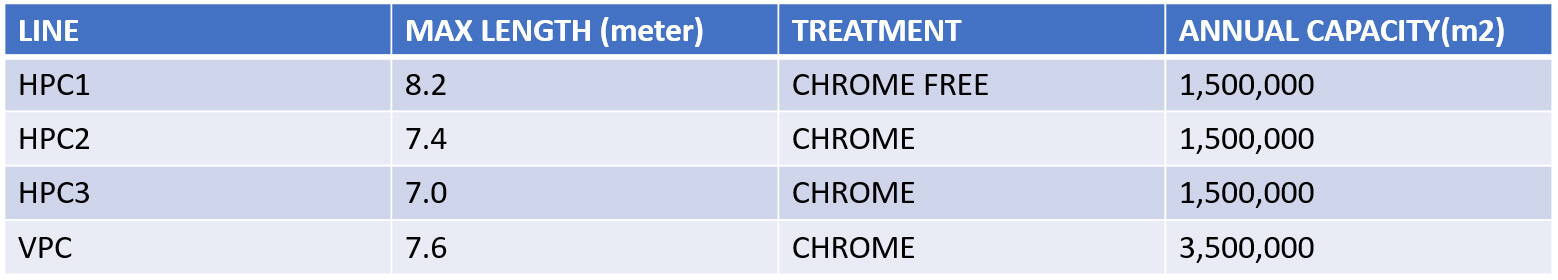

Gulf Extrusions LLC boasts impressive powder coating capabilities in the region. With four powder coating lines equipped with different and advanced technologies, Gulf Extrusions LLC can deliver high-quality finishes to their customers. The annual powder coating capacity of 8,500,000 square meters per year and ability to coat aluminium profiles up to 8.2 meter provides flexibility for various applications .These capabilities position Gulf Extrusions LLC as a significant player in the powder coating industry, capable of meeting diverse customer needs efficiently.

Plant Capabilities

- 3 Horizontal Lines and 1 Vertical Line.

- VPC Plant Capabilities: Up to 7.6 meters Profile Length.

- Max profile length: 8.2m.

- Treatment type: DIP TREATMENT (DIPPING BATH), CHROME FREE GARDOBOND.

POWDER COATING ADVANTAGES:

- Durability.

- Higher protection.

- Wide range of colour and finish.

- Friendly to the environment.

- Lower operational cost.

- Aesthetic and decoration.