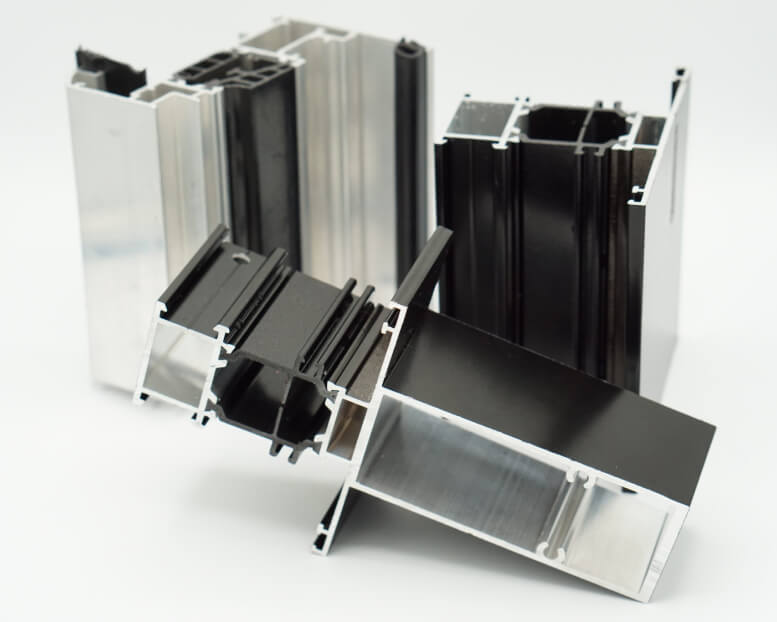

Crimping

Crimping is a service that we make available for our customers when they require lower conductivity by introducing polyamide strips into the required design as per the customer’s needs.

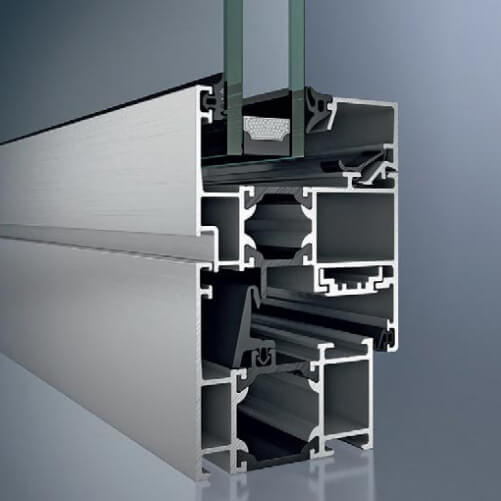

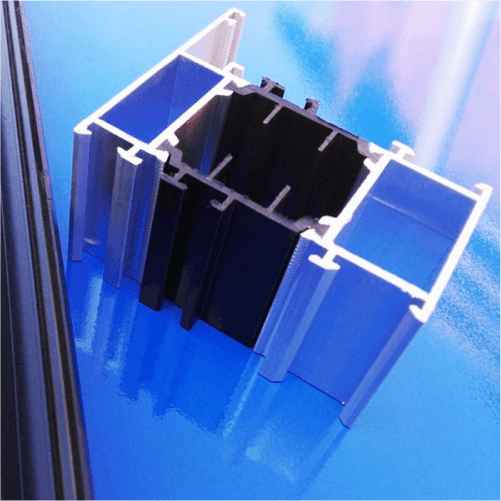

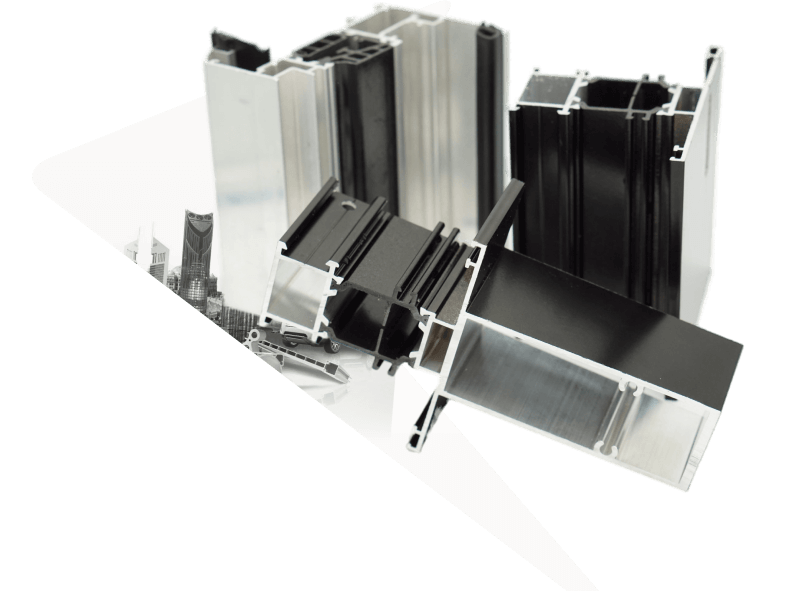

Under this process, the profiles of thermal break systems are joined together by means of a rigid and strong glass fibred polyamide insulation strip which has very low conductance as well as high structural strength, minimizing the thermal conductivity of aluminium.

Gulf Extrusions provides its customers with thermal break architectural systems that preserve all the benefits of aluminium – such as strength, durability and stability – while conserving energy, reducing water condensation as well as noise pollution. Our Thermal break systems offer increased thermal efficiency with higher shear and flexural strength characteristics over other equivalent systems, as well as allowing excellent system U-values.

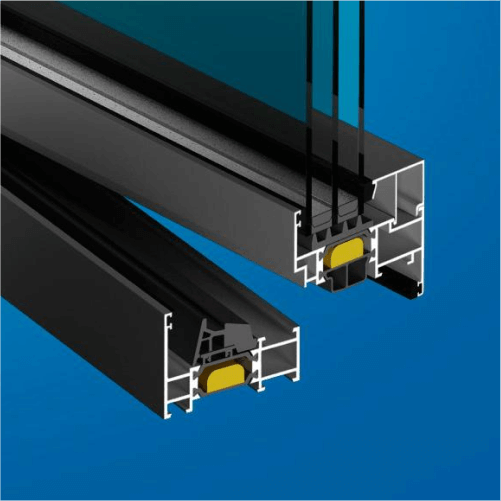

Framing Systems

Systems that are currently offered include:

- SS-600 Hinged Systems

- SS-900 Sliding Systems

- Thermal break Curtain Wall Systems

- Montana 120mm Sliding System

Benefits of Thermal Breaks

Reduced Condensation: A thermal break will minimize how much heat is lost from inside and how much cold is allowed through from the outside. Reducing cold spots and condensation forming.

Low U-Value: An aluminium window or door with a thermal break in it, will result in much lower heat loss through the framing.

Noise Reduction: By installing thermal break windows and doors, you will be able to stop noise by up to 80%.

Durability: thermal break structures are low maintenance, last longer, and are non-corrosive.

Added Security: Provides additional security and protection for your property.