Anodizing

Anodizing is an electrochemical process that converts a metal surface into a decorative, anodic oxide finish. The anodic oxide structure is made up of a layer of aluminium oxide on the surface of the aluminium which slightly increases the thickness of the metal.

The aluminium oxide fully integrated with the underlying aluminium profile, which protects aluminium from corrosion. It has a porous structure that allows for secondary processes such as colouring and sealing.

The anodizing process for aluminum not only enhances the appearance of aluminum but also improves its durability and corrosion resistance. The ability to dye the oxide layer opens up a wide range of possibilities for designers and manufacturers to achieve various aesthetic effects.

- What makes Gulf Extrusions different from others is that our anodizing capabilities for aluminum profiles goes up to 14 meters long, providing flexibility across various applications.

- Gulf Extrusions LLC wide range to customize the colour along with consistent Qulaity and longevity.

- Gulf Extrusions LLC capable to do the meticulously designed Pneumatic cylinders internal and external anodizing process.

- Gulf Extrusions LLC certified with ISO QUALANOD to do Anodizing, for all application profile like architecture, pneumatic cylinders, automotive & industrials profiles.

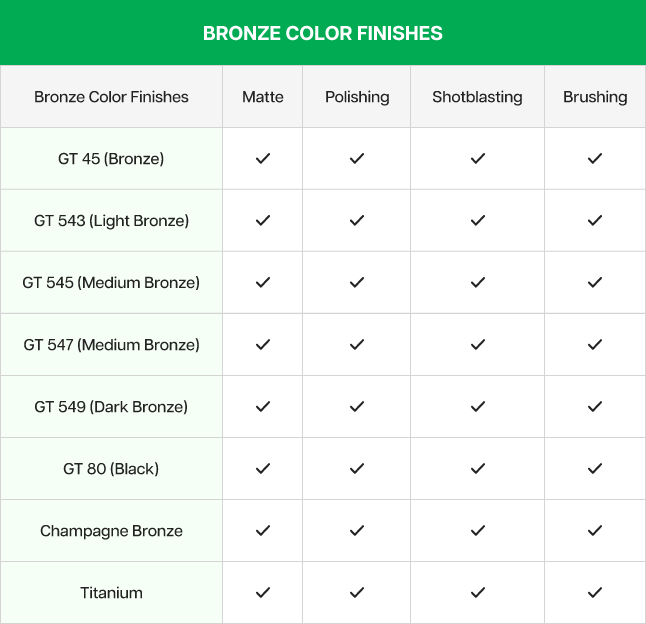

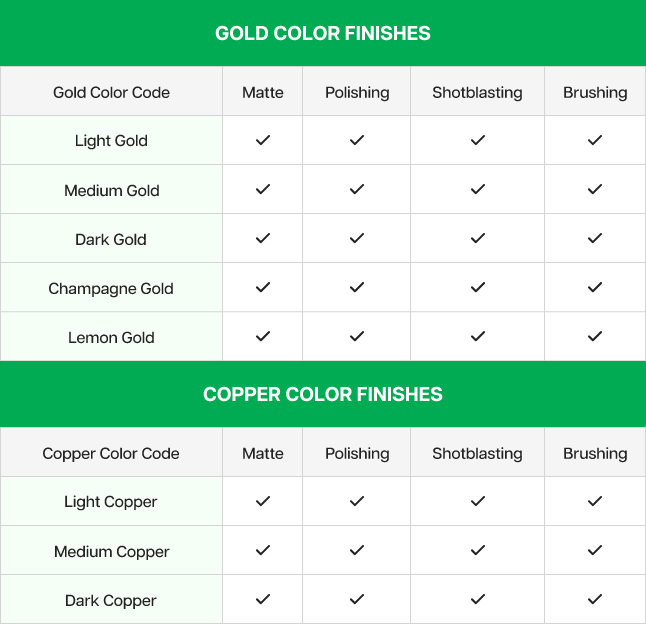

- Gulf Extrusions LLC Capable to do differenice surface finishes of Brushing. Polishing. Shotblasting and matte.

- Additionally, committed to environmental sustainability by offering 100% recyclable products and utilizing environmentally sustainable methods is commendable. This aspect is becoming increasingly important to customers and designers worldwide.

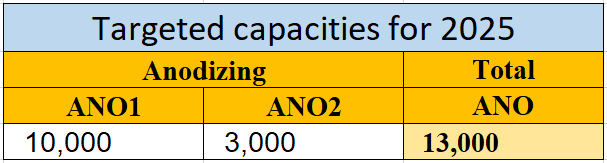

Plant capabilities :

Gulfex Colour Codes

Colour Codes with Different

Surface Finishes

Benefits of Anodizing

- Authentic metallic sheen, lustre and feel.

- Excellent Corrosion Resistance.

- Excellent Abrasion Resistance.

- No possibility of fading or chalking.

- No possibility of filiform corrosion.

- Uniform surface finish for all metal shapes and textures.

- Optimal Coverage & Highly impermeable anodic layer.

- Environmental benefits of pure anodised aluminium – 100% recyclable.

- Environmentally friendly production process in accordance with latest environmental standards.

- Long-term Guarantees.